The working principle of lithium ion battery

-------------------------------------------------------------

Li-ion battery (Li-ion, Lithium Ion Battery): Li-ion battery has advantages of light weight, large capacity, no memory effect, etc., so it has been widely used-now many digital devices are used Lithium-ion batteries are used as power sources, although their prices are relatively expensive. Lithium-ion battery has a high energy density, its capacity is 1.5 to 2 times that of a nickel-hydrogen battery of the same weight, and it has a very low self-discharge rate. In addition, lithium-ion batteries have almost no "memory effect" and do not contain toxic substances and other advantages are also important reasons for their wide application.

The working principle of lithium ion battery

Lithium ion battery Lithium ion battery principle structure Lithium battery is divided into lithium battery and lithium ion battery. Currently, mobile phones and laptops use lithium-ion batteries, which are commonly referred to as lithium batteries. Currently, lithium-ion batteries used in mobile phones, etc., but real lithium batteries are not used in daily electronic products due to their high risk.

Lithium-ion battery positive and negative materials

Lithium ion battery anode material is carbon material, lithium ion battery cathode material is a compound containing lithium, there is no metal lithium, only lithium ion, this is a lithium ion battery. Lithium ion battery refers to the general term for batteries with lithium ion intercalation compound as the cathode material. The charging and discharging process of lithium ion batteries is the process of intercalation and deintercalation of lithium ions. In the process of intercalation and deintercalation of lithium ions, it is accompanied by the intercalation and deintercalation of electrons equivalent to lithium ions (the positive electrode is usually represented by insertion or deintercalation, and the negative electrode is represented by insertion or deintercalation). During the charging and discharging process, lithium ions are intercalated/deintercalated and intercalated/deintercalated back and forth between the positive and negative electrodes, which is vividly called the "rocking chair battery".

Li-ion battery has high energy density and high average output voltage. The self-discharge is small, below 10% per month. There is no memory effect. The wide operating temperature range is -20℃~60℃. Excellent cycle performance, fast charging and discharging, charging efficiency up to 100%, and high output power. long lasting. There is no environmental pollution and it is called a green battery.

Charging is an important step for repeated use of batteries. The charging process of lithium-ion batteries is divided into two stages: constant current fast charging stage (the indicator light is red or yellow) and the constant voltage current decreasing stage (the indicator light is green). In the constant current fast charge stage, the battery voltage gradually rises to the battery standard voltage, and then switches to the constant voltage stage under the control chip. The voltage does not rise to ensure that it will not be overcharged, and the current gradually decreases as the battery power rises. To 0, and finally complete charging. The power statistics chip can sample and calculate the battery power by recording the discharge curve. The discharge curve of lithium-ion batteries will change after repeated use. Although lithium-ion batteries do not have a memory effect, improper charging will seriously affect battery performance.

Excessive charging and discharging of lithium-ion batteries will cause permanent damage to the positive and negative electrodes. Over-discharge causes the negative carbon sheet structure to collapse, and the collapse will cause the lithium ions to be unable to be inserted during the charging process; over-charging causes too many lithium ions to be inserted into the negative carbon structure, causing some of the lithium ions to be unable to be released anymore.

The charging capacity is equal to the charging current multiplied by the charging time. When the charging control voltage is constant, the larger the charging current (the faster the charging speed), the smaller the charging power. Excessive battery charging speed and improper termination voltage control point will also cause insufficient battery capacity. In fact, part of the electrode active material of the battery stops charging without sufficient reaction. This insufficient charging phenomenon increases with the increase in the number of cycles.

Lithium Ion Battery-Lithium Ion Battery Battery Components

Steel shell/aluminum shell series:

(1) Upper and lower battery cover

(2) Positive electrode-the active material is generally lithium cobalt oxide

(3) Diaphragm-a special composite membrane

(4) negative electrode-the active material is carbon

(5) Organic electrolyte

(6) Battery case (divided into steel case and aluminum case)

Flexible Packaging Series

(1) Positive electrode-the active material is generally lithium cobalt oxide

(2) Diaphragm-PP or PE composite film

(3) negative electrode-the active material is carbon

(4) Organic electrolyte

(5) Battery shell-aluminum-plastic composite film

The working principle of lithium ion battery

Lithium-ion battery schematic

When the battery is charged, lithium ions are generated on the positive electrode of the battery, and the generated lithium ions move to the negative electrode through the electrolyte. The carbon as the negative electrode has a layered structure. It has many micropores. The lithium ions reaching the negative electrode are embedded in the micropores of the carbon layer. The more lithium ions are inserted, the higher the charging capacity. Similarly, when the battery is discharged (that is, the process we use the battery), the lithium ions embedded in the carbon layer of the negative electrode are released and move back to the positive electrode. The more lithium ions returned to the positive electrode, the higher the discharge capacity.

Generally, the charging current of lithium batteries is set between 0.2C and 1C. The larger the current, the faster the charging and the greater the battery heat. Moreover, charging with an excessive current will result in insufficient capacity because the electrochemical reaction inside the battery takes time. Just like pouring beer, pouring too fast will produce foam, but dissatisfaction. For batteries, normal use is the process of discharging.

Lithium battery discharge needs to pay attention to several points:

First, the discharge current should not be too large. Excessive current will cause heat inside the battery, which may cause permanent damage. On mobile phones, this is not a problem, so you don't need to consider it.

Secondly, over-discharge is absolutely not allowed! Lithium batteries are most afraid of over-discharge. Once the discharge voltage is lower than 2.7V, the battery may be scrapped. Fortunately, a protection circuit has been installed inside the battery of the mobile phone, and the voltage is not low enough to damage the battery, the protection circuit will work and stop discharging. It can be seen from the figure that the larger the battery discharge current, the smaller the discharge capacity and the faster the voltage drop.

Lithium ion battery-safety hazard

Lithium-ion battery Lithium-ion battery The safety problem of lithium-ion battery is not only related to the nature of the cell material itself, but also related to the battery preparation technology and use. The frequent explosions of mobile phone batteries are due to the failure of the protection circuit on the one hand, but more importantly, the material has not fundamentally solved the problem.

The lithium cobalt oxide cathode active material is a very mature system in terms of small cells, but after fully charged, there are still a large amount of lithium ions left in the positive electrode. When overcharged, the lithium ions remaining in the positive electrode will rush to the negative electrode. The formation of dendrites on the negative electrode is an inevitable result of overcharging of batteries using lithium cobalt oxide materials. Even in the normal charge and discharge process, there may be excess lithium ions that dissociate to the negative electrode to form dendrites. The theoretical ratio of lithium cobalt oxide materials is The energy is more than 270 milliampere hours per gram, but in order to ensure its cycle performance, the actual use capacity is only half of the theoretical capacity. During use, due to some reasons (such as damage to the management system), the battery charging voltage is too high, a part of the remaining lithium in the positive electrode will be released, and the electrolyte will deposit on the surface of the negative electrode in the form of metal lithium to form dendrites. The dendrites pierce the diaphragm and form an internal short circuit.

The main component of electrolyte is carbonate, which has a very low flash point and low boiling point, and will burn or even explode under certain conditions. If the battery is overheated, the carbonate in the electrolyte will be oxidized and reduced, and a large amount of gas and more heat will be generated. If there is no safety valve or the gas is too late to be released through the safety valve, the internal pressure of the battery will rise sharply and cause an explosion.

The polymer electrolyte lithium ion battery does not fundamentally solve the safety problem. It also uses lithium cobalt oxide and organic electrolyte, and the electrolyte is gelatinous, not easy to leak, and will cause more violent combustion. Combustion is the safety of polymer batteries. The biggest problem of sex.

There are also some problems in the use of the battery, an external short circuit or an internal short circuit will generate an excessive current of several hundred amperes. When an external short circuit occurs, the battery is discharged with a large current instantly, which consumes a large amount of energy on the internal resistance and generates a huge amount of heat. The internal short-circuit forms a large current, and the temperature rise causes the diaphragm to melt, and the short-circuit area expands, thereby forming a vicious circle.

In order to achieve a high working voltage of 3~4.2V for a single cell, a lithium-ion battery must adopt an organic electrolyte with a decomposition voltage greater than 2V. The organic electrolyte will be electrolyzed under high current and high temperature conditions, and the electrolysis will produce gas. Causes the internal pressure to rise, severely breaking the shell.

Overcharge may cause metallic lithium to be precipitated. In the case of a shell rupture, direct contact with air will cause combustion, and the electrolyte will ignite at the same time, a strong flame will occur, the gas will expand rapidly, and an explosion will occur.

In addition, for mobile phone lithium-ion batteries, due to improper use, such as squeezing, impact and water ingress, the battery swells, deforms and cracks, etc., which will cause the battery to short-circuit and cause an explosion due to heat release during discharge or charging.

Lithium Ion Battery-Safety Design

Lithium-ion battery In order to avoid over-discharge or over-charge of the battery due to improper use, there is a triple protection mechanism in the single lithium-ion battery. One is the use of switching elements. When the temperature in the battery rises, its resistance will increase. When the temperature is too high, the power supply will be automatically stopped; the second is to select the appropriate separator material. When the temperature rises to a certain value, The micro-pores on the separator will automatically dissolve, so that lithium ions cannot pass through, and the internal reaction of the battery stops; the third is to set a safety valve (that is, the vent hole on the top of the battery), and when the internal pressure of the battery rises to a certain value, the safety valve Automatically open to ensure the safety of the battery.

Sometimes, although the battery itself has safety control measures, but the control fails due to some reasons, the lack of a safety valve or the gas is too late to release through the safety valve, the internal pressure of the battery will rise sharply and cause an explosion.

Under normal circumstances, the total energy stored by a lithium-ion battery is inversely proportional to its safety. As the battery capacity increases, the battery volume increases, its heat dissipation performance deteriorates, and the possibility of accidents will greatly increase. For lithium-ion batteries for mobile phones, the basic requirement is that the probability of a safety accident should be less than one in a million, which is also the lowest standard acceptable to the public. For large-capacity lithium-ion batteries, especially large-capacity lithium-ion batteries used in automobiles, it is particularly important to use forced heat dissipation.

Choose safer electrode materials and choose lithium manganate materials. In terms of molecular structure, it ensures that in the fully charged state, the lithium ions of the positive electrode have been completely embedded in the carbon pores of the negative electrode, which fundamentally avoids the generation of dendrites. At the same time, the stable structure of lithium manganate makes its oxidation performance far lower than that of lithium cobalt oxide, and its decomposition temperature exceeds 100°C for lithium cobalt oxide. Avoid the danger of burning and explosion due to the precipitation of metallic lithium.

In addition, the use of lithium manganate materials can also greatly reduce costs.

To improve the performance of existing safety control technology, the safety performance of lithium-ion battery cells must first be improved, which is particularly important for large-capacity batteries. Choose a separator with good thermal shutdown performance. The role of the separator is to allow lithium ions to pass through while isolating the positive and negative electrodes of the battery. When the temperature rises, it shuts down before the diaphragm melts, so that the internal resistance rises to 2000 ohms and the internal reaction stops.

When the internal pressure or temperature reaches the preset standard, the explosion-proof valve will open and begin to relieve the pressure to prevent the internal gas from accumulating too much, deforming, and finally causing the shell to burst.

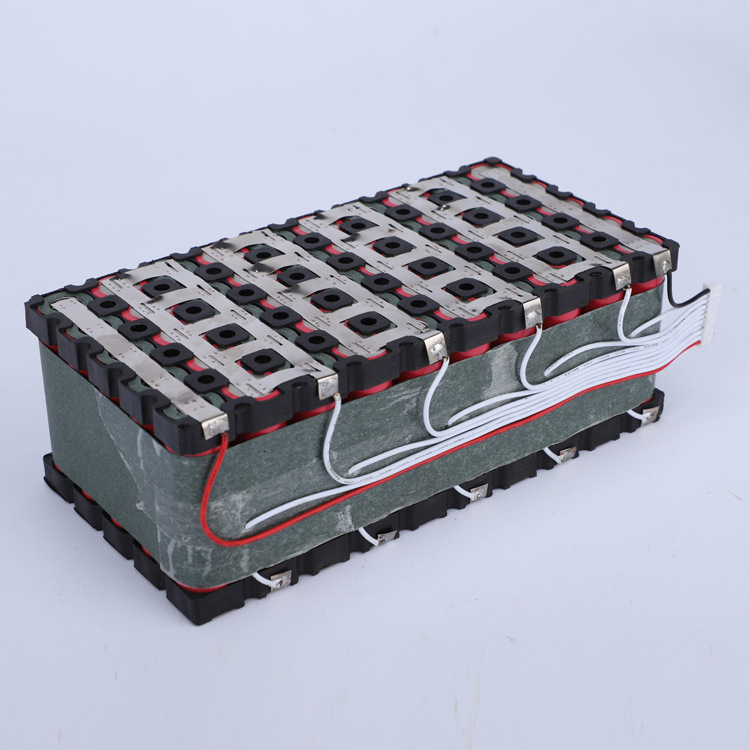

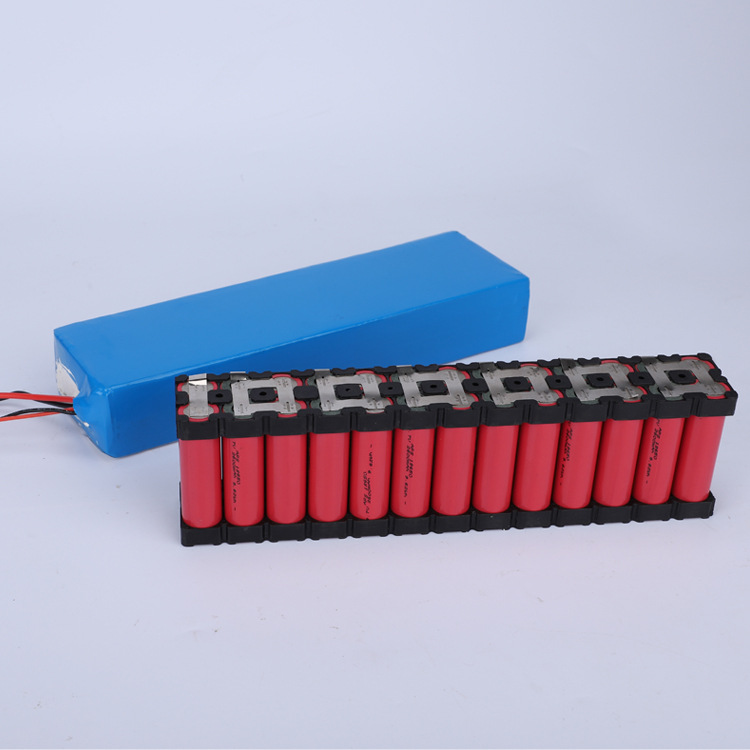

Improve control sensitivity, select more sensitive control parameters, and adopt joint control of multiple parameters (this is especially important for large-capacity batteries). For a large-capacity lithium-ion battery pack, it is composed of multiple cells in series/parallel. For example, the voltage of a notebook computer is more than 10V, and the capacity is large. Generally, 3 to 4 single cells can be connected in series to meet the voltage requirements, and then 2 ~ 3 battery packs connected in series are connected in parallel to ensure larger capacity.

The large-capacity battery pack itself must be equipped with a relatively complete protection function, and two circuit board modules should also be considered: the Protection Board PCB module and the Smart Battery Gauge Board module. The complete battery protection design includes: the first-level protection IC (to prevent battery overcharge, over-discharge, and short-circuit), the second-level protection IC (to prevent the second overvoltage), fuse, LED indication, temperature adjustment and other components.

Under the multi-level protection mechanism, even when the power charger or laptop is abnormal, the laptop battery can only be switched to the automatic protection state. If the situation is not serious, it will often work normally after re-plugging. There will be an explosion.

At present, the underlying technology of lithium-ion batteries used in notebook computers and mobile phones is not safe, and a safer structure needs to be considered.

In short, with the advancement of material technology and people's understanding of the requirements of the design, manufacture, testing and use of lithium-ion batteries, the future lithium-ion batteries will become safer.

Lithium Ion Battery-Type

Lithium-ion battery chargers for lithium-ion batteries There are many types of non-rechargeable lithium batteries. Currently, lithium-manganese dioxide batteries, lithium-thionyl chloride batteries, and lithium and other compound batteries are commonly used.

1.Lithium-manganese dioxide battery (LiMnO2)

Lithium-manganese dioxide battery is a disposable battery that uses lithium as anode, manganese dioxide as cathode, and organic electrolyte. The main feature of the battery is that the battery voltage is high, the rated voltage is 3V (2 times that of the general alkaline battery); the final discharge voltage is 2V; the specific energy is large (see the example above); the discharge voltage is stable and reliable; there is better Storage performance (storage time more than 3 years), low self-discharge rate (annual self-discharge rate ≤2%); working temperature range -20℃~+60℃.

The battery can be made into different shapes to meet different requirements. It has rectangular, cylindrical and button-shaped (button type).

Rechargeable lithium ion battery

The rechargeable lithium-ion battery is currently the most widely used battery in mobile phones, but it is more "squeaky" and cannot be overcharged or overdischarged during use (it will damage the battery or cause it to be scrapped). Therefore, there are protective components or protective circuits on the battery to prevent expensive battery damage. Lithium-ion battery charging requirements are very high. It is necessary to ensure that the termination voltage accuracy is within 1%. At present, major semiconductor device manufacturers have developed a variety of lithium-ion battery charging ICs to ensure safe, reliable, and fast charging.

Nowadays, mobile phones are very common. Some of the mobile phones are Ni-MH batteries, but smart phones are lithium-ion batteries. Proper use of lithium-ion batteries is very important to extend battery life. Lithium-ion batteries are currently the most widely used lithium batteries. They can be made into flat rectangles, cylinders, rectangles and button types according to the requirements of different electronic products, and there are battery packs composed of several batteries connected in series. The rated voltage of lithium-ion batteries is 3.6V (some products are 3.7V). The final charging voltage when fully charged is related to the anode material of the battery: the anode material is 4.2V of graphite; the anode material is 4.1V of coke. The internal resistance of different anode materials is also different, the internal resistance of the coke anode is slightly larger, and the discharge curve is also slightly different, as shown in Figure 1. Generally called 4.1V lithium ion battery and 4.2V lithium ion battery. Most of the batteries currently in use are 4.2V, and the termination discharge voltage of lithium-ion batteries is 2.5V~2.75V (the battery factory gives the operating voltage range or the termination discharge voltage, each parameter.

www.dtpbattery.com | info@dtpbattery.com | +86 755 23460581