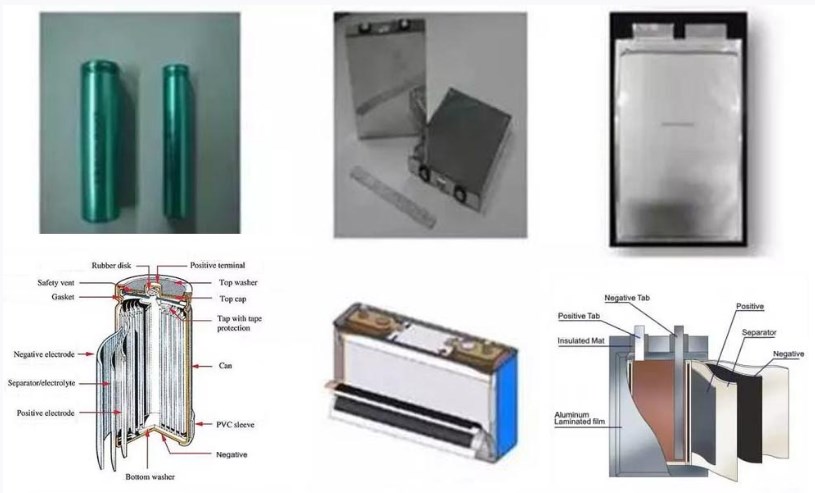

There are many devices that use batteries in our daily life, so what shapes do you know? Batteries, of course, that’s rechargeable lithium-ion batteries and as we all know, lead-acid batteries (usually standard size) are usually standard size, but lithium-ion batteries can come in a variety of packages and shape battery.

One of the most common misconceptions is that polymer batteries are different. In fact, they are one of the most common types of lithium-ion batteries, assembled and packaged in flat, bag-like shapes. Their core design is based on standard lithium-ion chemistry. They are called “polymer” batteries because they tend to use gel-like rather than liquid-like electrolytes. The outer packing is a thin foil that holds the inner structure together. As a result, they can be easily damaged or punctured, and are often (if not always embedded in mobile devices) protected mechanically.

One of the advantages of polymer batteries is that they can be manufactured in almost any custom size or shape. This ability to make batteries suitable for mobile devices, not vice versa, makes polymer batteries extremely attractive. Polymer batteries can also be made very thin. This photo shows a polymer battery made by GREPOW for smart CARDS. It’s only about 0.4 millimeters thick. The drawback of polymer batteries is the lack of standardization, which makes them expensive. Each battery model must be designed and shaped to a specific size for a mobile device manufacturer. Polymer batteries cost nearly twice as much (for the same amount of stored energy) as comparable standard 18650 batteries.

The naming of the 18650 battery is hardly creative. It was a standard cylinder 18mm in diameter and 65mm in height, hence the name. Over the past decade, the standard size of these batteries has made them ubiquitous and cheap. They are widely used in laptops, but they have proved less practical for thin smartphones. Tesla Motors took advantage of mass production and the low cost of the 18650 to use in electric vehicles. The Tesla Model S’s battery pack contains nearly 7,000 such cells. Panasonic’s 18650 battery has a capacity of 3,400 mAh.It’s similar to the ones used in Tesla cars. Other major makers of electric cars have opted for large-size polymer batteries. Still, there are 18650.

The third type of battery is called prismatic. They are very similar in nature to polymer batteries but are packaged in solid casings or tanks usually made of aluminum alloy. This provides additional mechanical protection and necessary safety. Mobile devices that offer replaceable batteries use square batteries. Prismatic cells tend to be thicker than polymer cells because of the walls of the external tank.

Keen readers may ask questions about the connector to the SONY polymer battery. In fact, it’s an electrical connector made from thin, flexible cables. At the tip of this cable, you can observe some of the circuits that provide the necessary electronic protection for the battery. In particular, the circuit ensures that the battery is not subjected to excessive voltages or currents. If the battery is exposed to adverse conditions, the built-in fuse disconnects the battery. Similar circuits are embedded inside prismatic cells. However, the 18650 battery is bare, that is, it does not include any such protection circuit, which must be included in the external battery management system before the battery can be used.

Above is the battery knowledge that DATA POWER shares with you. If you are interested in BATTERY, want to learn more about different shapes of battery information, please contact the DTP office at info@dtpbattery.com. More information can be found at https://www.dtpbattery.com/